In today's manufacturing landscape, the production of cast iron rolls exemplifies a harmonious blend of traditional craftsmanship and cutting-edge technology. These rolls, integral to various industrial processes like metal forming and rolling mills, owe their efficacy to the meticulous balance between age-old techniques and modern innovations.

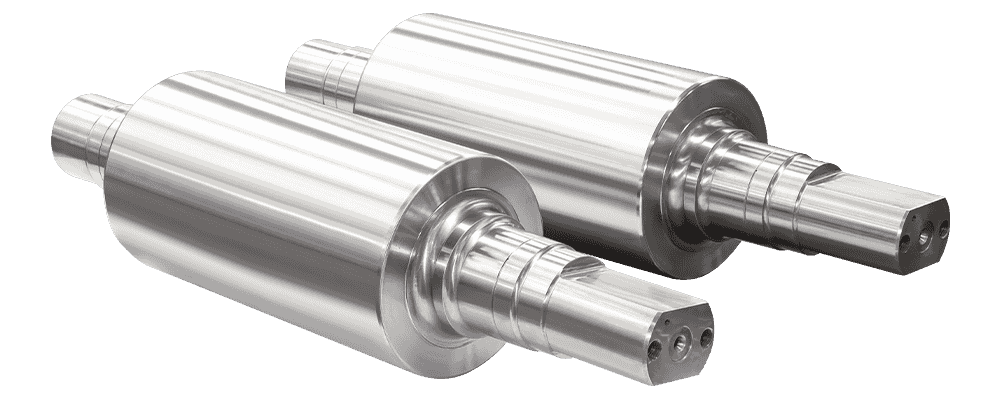

Cast iron rolls offer distinct advantages in industrial applications due to their exceptional hardness, wear resistance, and thermal conductivity. These properties make them ideal for withstanding the high pressures, temperatures, and repetitive stresses encountered in rolling operations. Moreover, their ability to maintain dimensional stability under heavy loads ensures consistent product quality and operational efficiency.

Traditional craftsmanship plays a pivotal role in the initial stages of cast iron roll production. Skilled pattern makers meticulously craft the wooden patterns that serve as molds for casting. These patterns are crafted with precision to replicate the intricate contours and specifications required for each roll design. The foundry process, a cornerstone of traditional manufacturing, involves skilled foundry workers who manage the intricate choreography of melting iron and pouring it into molds. This process demands expertise in controlling temperatures, managing the flow of molten metal, and ensuring uniform casting to avoid defects.

Traditional craftsmanship plays a pivotal role in the initial stages of cast iron roll production. Skilled pattern makers meticulously craft the wooden patterns that serve as molds for casting. These patterns are crafted with precision to replicate the intricate contours and specifications required for each roll design. The foundry process, a cornerstone of traditional manufacturing, involves skilled foundry workers who manage the intricate choreography of melting iron and pouring it into molds. This process demands expertise in controlling temperatures, managing the flow of molten metal, and ensuring uniform casting to avoid defects.

Once cast, the rolls undergo meticulous machining and finishing processes. Traditional machinists utilize their expertise to ensure that each roll meets precise dimensional tolerances and surface finish requirements. This stage requires careful attention to detail, as even minor deviations can impact the roll's performance and longevity in industrial settings.

In tandem with traditional craftsmanship, modern technology revolutionizes various aspects of cast iron roll production. Advanced CAD software enables engineers to design rolls with unparalleled precision, optimizing their geometries for strength, heat dissipation, and operational durability. Simulation tools further refine these designs, predicting performance under different operating conditions and guiding improvements in material selection and casting techniques.

Material science plays a crucial role in enhancing the properties of cast iron rolls. Engineers leverage their knowledge to develop specialized alloys and heat treatments that improve wear resistance, reduce thermal distortion, and enhance overall performance. This integration of metallurgical advancements ensures that modern cast iron rolls not only meet but exceed the rigorous demands of contemporary industrial applications.

Quality control is another area where modern technology excels in the production of cast iron rolls. Advanced testing methods such as non-destructive testing (NDT), ultrasonic testing, and X-ray inspection ensure the integrity of each roll, detecting internal defects and verifying dimensional accuracy. These technologies not only uphold stringent quality standards but also contribute to the reliability and longevity of cast iron rolls in service.

Moreover, the advent of automation has streamlined several production processes, from automated pouring systems in foundries to CNC machining centers for precise shaping and finishing. Automation enhances consistency, efficiency, and repeatability in manufacturing, further bolstering the reliability and performance of cast iron rolls.

The production of cast iron rolls today exemplifies a symbiotic relationship between traditional craftsmanship and modern technology. While traditional skills in pattern making, foundry work, and machining uphold the foundational principles of quality and precision, modern advancements in design, material science, automation, and quality control propel these rolls to new heights of performance and reliability. This harmonious integration ensures that cast iron rolls continue to play a vital role in powering industrial processes worldwide, delivering durability, efficiency, and consistent quality in the face of demanding operational conditions.